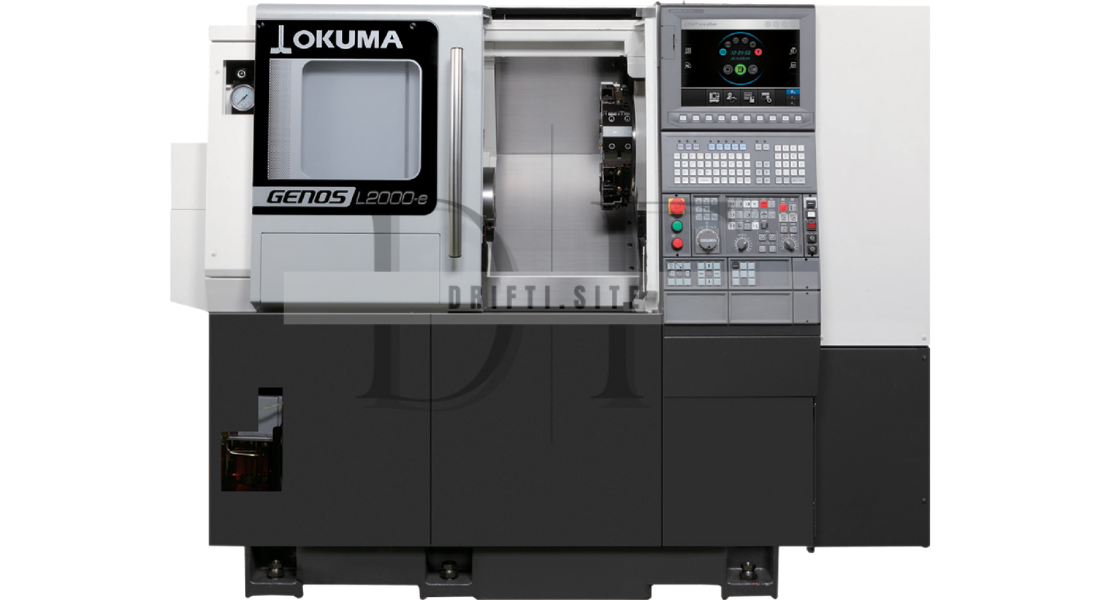

When it comes to achieving top-tier precision and efficiency in machining, the Okuma Genos L200EM CNC lathe is a game-changer. With cutting-edge technology and remarkable versatility, this machine delivers a perfect blend of power, accuracy, and usability for manufacturers across various industries. Whether you’re working in automotive, aerospace, or medical device production, the Okuma Genos L200EM stands out as a reliable and efficient solution for your machining needs. In this article, we will dive deep into the features, advantages, and why this CNC lathe is gaining popularity among professionals.

Why the Okuma Genos L200EM CNC Lathe is a Top Choice for Professionals

The Okuma Genos L200EM is engineered to meet the needs of modern machining environments, combining advanced technology with user-friendly features. It is designed to provide exceptional precision and reliability in a compact and affordable package. This makes it an ideal choice for job shops, small and medium manufacturers, and large enterprises alike.

With an emphasis on high-speed cutting, reduced downtime, and easy operation, the Genos L200EM CNC lathe helps users achieve maximum productivity and cost-effectiveness. The machine’s design ensures that operators can create high-quality parts with incredible accuracy while maintaining the utmost efficiency.

High-Speed Machining with Enhanced Precision

One of the standout features of the Okuma Genos L200EM is its high-speed machining capability. Equipped with a powerful 15 hp spindle motor, this CNC lathe is capable of producing parts quickly while maintaining exceptional precision. The machine’s fast spindle speeds and rapid traverse rates reduce cycle times significantly, allowing manufacturers to meet tight deadlines and increase overall throughput.

In addition, the Genos L200EM features Okuma’s high-precision spindle bearings and linear guideways, which ensure smooth and accurate movements. The result is reduced vibration and enhanced surface finishes, making it ideal for machining high-precision parts in industries like aerospace and medical manufacturing.

Versatile and Adaptable for a Range of Applications

The Okuma Genos L200EM is designed to accommodate a variety of applications, thanks to its versatility and customizable configurations. Whether you need to machine small, complex components or larger, more straightforward parts, this CNC lathe can handle it all.

The lathe’s tailstock and live tooling options provide flexibility in part setups, making it easier to create a wide range of components without changing tools or setups constantly. Additionally, the L200EM can be configured with different spindle options, allowing it to meet specific machining requirements depending on the material or part complexity.

For manufacturers that work with a wide range of materials, the Okuma Genos L200EM can handle everything from soft metals to hard, heat-treated alloys with ease. Whether you’re machining aluminum, stainless steel, or titanium, this lathe offers consistent performance across a broad spectrum of materials.

Okuma’s Thermo-Friendly Concept for Stable Performance

One of the key factors that set the Okuma Genos L200EM apart from other CNC lathes is the incorporation of Okuma’s Thermo-Friendly Concept (TFC). This technology helps to compensate for temperature variations during machining, which can otherwise lead to inaccuracies or dimensional drift.

Temperature fluctuations can cause thermal expansion of the machine components, impacting machining tolerances. Okuma’s TFC system uses advanced algorithms to adjust for these changes, ensuring that the lathe maintains its accuracy and stability throughout the production process. This makes the Genos L200EM an ideal choice for manufacturers that require consistent precision across extended production runs, even under fluctuating shop temperatures.

User-Friendly Operation with Advanced Control Systems

The Okuma Genos L200EM doesn’t just deliver power and precision – it’s also designed with ease of operation in mind. The machine comes equipped with the Okuma OSP-P300 CNC control system, which provides an intuitive interface that makes programming and operation easy for both experienced and novice operators. The control system allows users to quickly input commands, monitor the machine’s performance, and make adjustments in real-time.

The OSP-P300 system also includes advanced diagnostics and real-time feedback, which help operators detect potential issues before they lead to downtime or defects. The system is designed to reduce the learning curve for new users, making it easier for staff to quickly get up to speed with the machine and start producing quality parts from the first day.

Additionally, the Genos L200EM comes with a high-visibility LCD screen and ergonomic controls, which ensure that the operator has a clear view of the machining process at all times. This allows for greater control and a more streamlined workflow, reducing errors and increasing overall productivity.

Reliable and Efficient Cutting Power

The Okuma Genos L200EM delivers exceptional cutting power and efficiency, making it a top choice for high-volume production. The lathe is equipped with a high-torque spindle motor that provides reliable cutting performance, even when working with tough materials like hardened steel or titanium. This ensures that you can maintain high cutting speeds without sacrificing surface finish or part quality.

For precision turning, the L200EM offers advanced C-axis indexing and live tooling, which enable multi-axis machining in a single setup. This eliminates the need for multiple machines and setups, increasing overall efficiency and reducing cycle times.

Moreover, the machine’s tool change time is fast, ensuring that tool changes do not lead to significant delays in the machining process. With the combination of fast spindle speeds, rapid tool changes, and the ability to perform complex cuts, the Genos L200EM offers industry-leading cutting power that helps improve production efficiency.

Low Maintenance and High Durability

The Okuma Genos L200EM is designed to be both durable and easy to maintain. Okuma’s attention to detail in the construction of the L200EM ensures that it can withstand the demands of high-volume production while requiring minimal maintenance. The machine’s sealed bearings and durable guideways ensure long-lasting performance, even in harsh operating environments.

Regular maintenance tasks are streamlined thanks to the easy access design of the machine. Key components, including the spindle and cooling system, are easy to reach for routine checks and maintenance, which reduces downtime and extends the life of the machine.

Okuma also offers a comprehensive warranty and after-sales support, providing peace of mind that your Genos L200EM lathe is backed by the expertise of one of the leading names in CNC manufacturing.

Compact Design for Space-Efficient Manufacturing

For many manufacturers, space is a premium, especially in smaller workshops or busy production floors. The Okuma Genos L200EM is designed to offer high-performance machining in a compact footprint, allowing businesses to maximize their workspace without sacrificing capabilities.

Despite its compact size, the Genos L200EM doesn’t compromise on its cutting capabilities. The machine’s efficient layout makes it possible to install it in tight spaces while still providing the high-powered performance you need. This compact design also helps reduce operational costs, as it takes up less valuable floor space and can be operated efficiently in smaller workshops.

Why Choose the Okuma Genos L200EM CNC Lathe?

The Okuma Genos L200EM offers a range of features that make it a top choice for manufacturers looking for a CNC lathe that delivers both precision and productivity. Here’s why it stands out:

- High-Speed Machining: With fast spindle speeds and rapid traverse rates, the L200EM reduces cycle times, allowing you to increase throughput and meet tight deadlines.

- Thermo-Friendly Concept: Okuma’s advanced thermal compensation technology ensures the machine maintains its precision and stability, even in fluctuating shop temperatures.

- Versatility: The Genos L200EM is designed for a variety of applications, from small, complex parts to larger components, and it can work with a wide range of materials.

- User-Friendly Control: The OSP-P300 CNC control system makes it easy for operators to program, monitor, and adjust the machine, improving overall efficiency and reducing errors.

- Durability and Reliability: With Okuma’s robust engineering, the L200EM is built to last, requiring minimal maintenance while delivering consistent, high-quality results.

Conclusion: The Okuma Genos L200EM CNC Lathe is a Must-Have for Precision Manufacturing

The Okuma Genos L200EM CNC lathe is a standout machine for manufacturers who need reliable, efficient, and precise machining capabilities. With its high-speed performance, versatile features, and user-friendly design, it’s an excellent choice for businesses looking to streamline production, improve quality, and meet customer demands with ease.

Whether you’re in the automotive, aerospace, or medical industry, the Genos L200EM offers everything you need to stay competitive and deliver high-quality results every time. With Okuma’s reputation for quality and innovation, the L200EM ensures that your manufacturing operations will continue to run smoothly and efficiently for years to come.